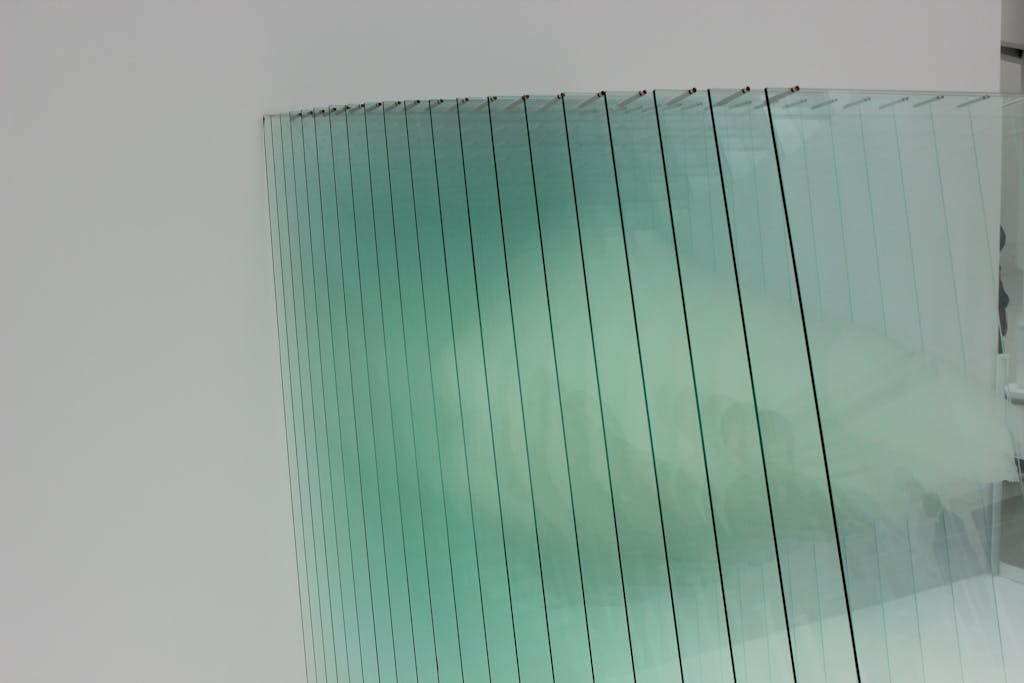

How AI Is Supporting Sustainability Goals in the Glass Industry

Worldwide, glass manufacturing is a booming industry that asks manufacturers to produce a quality product but also reduce waste. This begs the question: How can we dramatically reduce the glass industry’s environmental impact without sacrificing its indispensable products? One promising answer is through the strategic use of artificial intelligence (AI). By leveraging data-driven insights and machine learning, AI is enabling glass manufacturers to optimize their processes in ways that cut emissions, save energy, reduce waste, and boost recycling.

How AI Is Supporting Sustainability Goals in the Glass Industry

AI technologies are helping glass manufacturers meet ambitious sustainability objectives:

- Lowering emissions: AI process controls optimize furnace efficiency to cut CO₂ output.

- Improving energy efficiency: AI adjusts equipment parameters to minimize energy use.

- Reducing waste: Predictive maintenance and AI quality control limit scrap.

- Increasing recycling: Smart sorting systems powered by AI boost cullet recovery.

Let’s take a closer look at each of these contributions.

Optimizing Energy and Emissions with AI

Furnaces are energy-intensive and a major source of CO₂. AI now plays a key role in optimizing these systems. By analyzing live data on temperature, fuel flow, and oxygen levels, AI fine-tunes the process in real time.

For instance, O-I Glass installed an AI-powered energy management system at its UK plant. Paired with battery storage, the AI determines when to charge or discharge to reduce demand on the grid. This system is projected to save 240 tons of CO₂ annually at that facility.

Beyond energy storage, AI-based furnace control systems constantly adjust settings to burn more cleanly and efficiently, without compromising product quality. Predictive analytics help forecast when components will degrade, allowing proactive maintenance and preventing fuel waste.

Improving Quality and Reducing Waste

AI improves yield by catching problems early. Machine vision systems inspect for bubbles, scratches, or warping and adjust production conditions before waste builds up. One case study showed how AI reduced cleaning time of forming molds from 5 hours to just 2 seconds, resulting in huge raw material and energy savings.

Causal AI tools can identify subtle process variations that lead to defects. When combined with predictive maintenance, these tools ensure consistent quality with minimal downtime. This leads to less scrap, fewer energy-wasting restarts, and better use of raw materials.

Boosting Circularity Through Smart Recycling

Glass is 100% recyclable, but sorting cullet efficiently is a major challenge. AI-enabled optical sorters now recognize glass by color, shape, and composition, separating contaminants and improving recovery.

By increasing cullet usage, glassmakers lower the need for virgin raw materials and cut energy consumption in melting. Every 10% increase in cullet can lead to about 3% energy savings and 7% fewer emissions.

Where the Industry Is Headed

At GMIC, we support our members in applying technologies like AI to meet environmental and operational goals. As more plants adopt smart manufacturing systems, we’re seeing:

- Better data collection and sharing across plants

- Collaboration between OEMs, tech providers, and producers

- Scaling of pilot AI programs to full production lines

AI isn’t replacing skilled operators—it’s augmenting their decision-making. From fine-tuning processes to improving sustainability metrics, AI is enabling a cleaner, more efficient future for glass manufacturing.

Conclusion

How AI Is Supporting Sustainability Goals in the Glass Industry comes down to its ability to drive efficiency at every stage: cleaner melting, better quality, smarter maintenance, and more recycling. These gains align with GMIC’s mission to promote sustainable innovation.

As we work toward a greener industry, AI is not just a buzzword—it’s a tool helping us make meaningful progress. The companies leading the way are proving that glass can be both high-performance and low-impact.

JOIN GMIC

JOIN GMIC